The Future of Embedded Systems: Displays and SBCs Driving Innovation

Explore the future of embedded systems through innovations in IPS display technology, optical bonding, and Android SBC integration — reshaping how industrial, medical, and consumer devices deliver performance and usability.

Introduction

The landscape of embedded systems is transforming rapidly. Once considered niche, they are now the backbone of modern devices — from industrial automation to consumer electronics.

At the heart of this transformation lie two core technologies: display systems and single-board computers (SBCs).

This article explores how IPS displays, optical bonding techniques, and Android-based SBCs are redefining performance, reliability, and user experience in next-generation embedded products.

Why Displays Matter in Embedded Devices

Displays are no longer passive output components — they have become the primary human–machine interface.

In industries like medical imaging, industrial control, and smart home automation, the screen often determines whether a product feels intuitive, premium, and reliable.

Modern expectations include:

- High readability indoors and outdoors

- Accurate color rendering for medical and industrial use

- Durability against vibration, impact, and temperature variations

Beyond resolution, what truly matters are anti-glare coatings, optical bonding, and responsive touch performance.

Outdoor Readability: Anti-Glare vs. Anti-Reflection

For outdoor devices, sunlight readability is one of the biggest challenges. Two major surface treatments address this:

🟢 Anti-Glare (AG)

AG coatings scatter incoming light, reducing reflections but slightly softening image sharpness.

They’re widely used in cost-sensitive products like consumer tablets or entry-level kiosks.

🔵 Anti-Reflection (AR)

AR coatings minimize surface reflectivity while maintaining crisp visuals.

They’re preferred for medical, industrial, and aerospace applications — where clarity and accuracy are critical.

When paired with high-brightness backlights, both AG and AR coatings drastically improve visibility in bright conditions.

Optical Bonding: Bridging Technology and Usability

Optical bonding involves laminating the TFT panel and its cover glass using an adhesive (OCA or OCR).

This process removes the air gap and yields several major benefits:

- Better sunlight readability (reduced internal reflections)

- Enhanced ruggedness against dust, moisture, and shock

- Improved touch sensitivity due to shorter optical distance

Although bonding increases production costs, it’s the preferred method for mission-critical devices such as medical monitors, outdoor kiosks, and industrial HMIs, where clarity and reliability matter most.

Single-Board Computers: Compact Powerhouses

On the computing side, SBCs act as the “brains” of embedded devices.

Unlike multi-board systems, they integrate CPU, GPU, memory, storage, and I/O interfaces on a single compact board.

Key Benefits

- Compact and space-efficient form factor

- Energy efficiency for battery-powered products

- Scalable performance (from entry-level ARM to high-end x86)

- Simplified integration with displays and sensors

Combining a modern SBC with an advanced display enables a wide range of designs — from handheld analyzers to wall-mounted smart panels.

Real-World Applications

🏥 Medical Devices

Accurate colors and stable performance are critical in diagnostics.

Optical bonding prevents dust or condensation from distorting medical images.

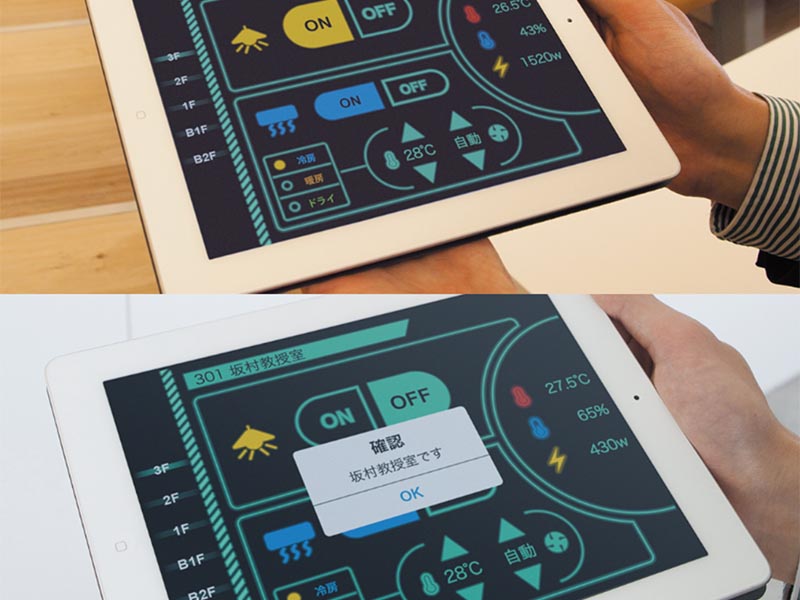

🏠 Smart Homes

Wall-mounted control panels pair Android SBCs with IPS touch displays.

Anti-glare coatings ensure comfortable use in naturally lit environments.

🏭 Industrial Automation

Factories rely on bonded displays for control interfaces that withstand vibration and dust.

SBCs deliver real-time data processing with low latency.

🚏 Outdoor Kiosks & Signage

High-brightness AR-coated screens maintain readability under sunlight,

while Android-based SBCs streamline content updates and remote management.

Looking Ahead: Integration and Customization

The next evolution in embedded systems will focus on deep integration between displays and computing units.

It’s no longer about selecting them separately — success depends on co-designing both.

Emerging trends include:

- Thinner optical adhesives for lightweight form factors

- High-efficiency LED backlights with reduced power draw

- AI-ready SBCs supporting local machine learning and predictive analytics

Companies that master this integration will lead the next generation of industrial, automotive, and medical innovations.

Conclusion

Embedded systems are evolving fast. Displays are now the primary interface defining user experience, while SBCs are becoming smarter, smaller, and more capable.

From anti-glare coatings to optical bonding, and from Linux to Android-based SBCs, the choices engineers make today determine how tomorrow’s devices will perform.

By pairing the right display technology with the right SBC platform, designers can build solutions that are not only functional — but also intuitive, robust, and future-ready.