Android SBCs in Industrial Automation: Bridging Human Interfaces and Intelligent Control

Explore how Android single-board computers are transforming industrial automation systems through intuitive HMI design, real-time connectivity, and long-term reliability.

Introduction

The era of Industry 4.0 has reshaped how factories and production lines operate.

Automation is no longer just about replacing human labor — it’s about connecting machines, data, and people through intelligent systems that respond in real time.

At the center of this evolution lies a versatile class of hardware: Android Single Board Computers (SBCs).

Traditionally, industrial automation relied on PLCs, RTOS controllers, and Linux-based HMIs.

But as interfaces become more visual and connectivity demands grow, Android SBCs have emerged as an ideal solution — merging multimedia performance with flexible networking and intuitive human-machine interaction (HMI).

What Makes Android SBCs Suitable for Industrial Automation?

An Android SBC is a compact embedded board that runs a full Android operating system on ARM or x86 architecture.

It integrates the CPU, GPU, memory, storage, and I/O interfaces into a single platform, simplifying system integration while enabling high-level functionality such as:

- Touch-based HMI design

- Real-time monitoring dashboards

- IoT and cloud connectivity

- Edge AI and predictive maintenance

- Secure data logging and firmware updates

Unlike traditional embedded platforms, Android SBCs bring a familiar development environment and rapid prototyping capability to industrial product teams.

Hardware Architecture Overview

A modern industrial Android SBC typically includes:

SoC (System-on-Chip)

- Multi-core ARM Cortex-A55 or A76 CPU

- Integrated GPU for OpenGL ES and hardware-accelerated graphics

- Optional NPU for AI-based vision or diagnostics

Memory and Storage

- 2GB–8GB DDR4 RAM

- eMMC or SD storage (expandable up to 128GB)

Display and Touch Interface

- MIPI DSI, LVDS, or HDMI support

- Capacitive (PCAP) or resistive touch input

Industrial I/O

- UART, RS-485/RS-232

- CAN bus for machine communication

- GPIOs for sensors, buttons, and relays

Networking

- Ethernet (10/100/1000 Mbps)

- Wi-Fi and Bluetooth for wireless control

- Optional 4G/5G or LoRa modules

Power and Reliability

- Wide voltage input (9–36V DC)

- Operating temperature range −20°C to +70°C

- ESD and surge protection for industrial robustness

This combination allows Android SBCs to function as the “brains” of an automation terminal or gateway device — capable of running graphical applications, handling data processing, and interfacing directly with field sensors.

Advantages of Using Android SBCs in Automation

1. Intuitive Human-Machine Interfaces (HMI)

Modern automation systems demand intuitive, responsive, and visually appealing interfaces.

Android’s UI framework — built on Java, Kotlin, and XML layouts — allows engineers to design touch-friendly HMIs with dynamic graphics, charts, and multi-language support.

Operators can control complex systems through easy-to-use panels featuring clear status displays, alarms, and parameter inputs.

2. Connectivity and IoT Integration

Android provides native support for Ethernet, Wi-Fi, MQTT, HTTP, and WebSocket protocols, making it ideal for Industrial IoT (IIoT) applications.

Android SBCs can transmit real-time machine data to the cloud or MES (Manufacturing Execution System), enabling predictive maintenance and data-driven decision-making.

3. Edge Computing and AI Readiness

With integrated GPUs and NPUs, many SBCs are now capable of running machine vision and AI models locally.

This reduces dependency on cloud computation and improves latency for applications such as:

- Defect detection using AI cameras

- Worker presence verification

- Equipment anomaly detection

- Visual sorting systems

Android’s TensorFlow Lite and NNAPI frameworks simplify deployment of edge AI models.

4. Cost Efficiency and Rapid Development

Android SBCs drastically reduce development cycles compared to proprietary platforms.

With existing SDKs, open-source drivers, and Android Studio integration, developers can go from prototype to production in weeks — not months.

At scale, the overall cost per unit is lower than many Windows- or Linux-based HMIs.

5. Long-Term Maintenance and OTA Updates

Firmware updates can be distributed over-the-air using Android’s built-in OTA (Over-The-Air) mechanism.

Manufacturers can release software improvements, security patches, and new UI features without physical access to the device — reducing maintenance costs in large-scale deployments.

Typical Industrial Applications

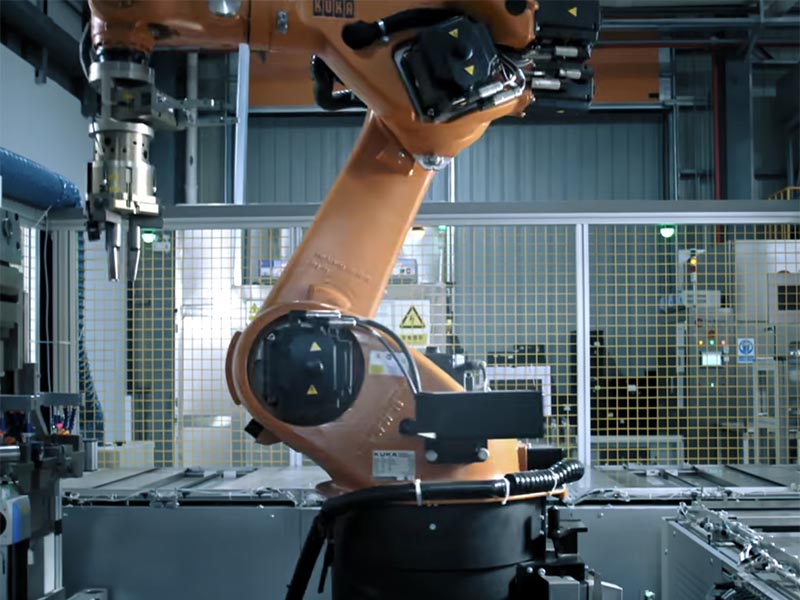

1. Factory HMIs and Control Panels

Android SBCs serve as the core of wall-mounted or panel-mounted operator terminals.

Their ability to render high-resolution touch interfaces makes them perfect for:

- Conveyor system control

- Robot arm programming

- Process visualization dashboards

These HMIs often connect via RS-485 or Ethernet to PLCs, relaying data while providing real-time feedback.

2. Energy and Power Management Systems

Smart power distribution systems use Android SBCs to monitor voltage, current, and load status.

The built-in UI allows technicians to visualize trends, manage alarms, and access data logs without needing a PC.

3. Industrial Gateways and Data Concentrators

With multiple I/O ports and networking options, Android SBCs act as gateways between legacy equipment and cloud services.

They can gather sensor data, run local filtering algorithms, and forward key metrics to remote dashboards.

4. Smart Building and Environmental Control

Building automation systems benefit from Android’s graphical and wireless capabilities.

SBCs can control lighting, HVAC systems, and security devices while offering sleek, tablet-like user interfaces for operators.

5. Machine Vision and Quality Inspection

When combined with USB or MIPI cameras, Android SBCs can run lightweight computer vision models for defect detection or product alignment in manufacturing lines.

Software Development Considerations

BSP Customization

To adapt Android to industrial use, engineers often modify the Board Support Package (BSP) to include:

- Real-time UART or RS-485 drivers

- Extended watchdog support

- GPIO interrupt handling

- Thermal and voltage monitoring

This ensures reliable operation even in harsh industrial environments.

UI and UX Optimization

For industrial applications, UI performance and stability take priority over animation effects.

Engineers often design HMIs using Jetpack Compose or native Android Views with minimal background tasks to ensure responsiveness under heavy system load.

Security and Access Control

Industrial devices must prevent unauthorized access.

Android’s multi-user framework, secure boot, and hardware encryption modules (e.g., TPM or ATECC608) help safeguard system integrity and communication.

Integration with PLCs and Field Protocols

Many SBCs support Modbus TCP/RTU, CANopen, or Profinet through dedicated libraries or external converters.

Android applications can communicate with these systems using serial APIs or socket connections, enabling interoperability between automation layers.

Hardware Design and Deployment Tips

Thermal Management:

Use aluminum enclosures or heat spreaders to dissipate heat from the SoC during continuous operation.Power Protection:

Add transient suppression diodes and EMI filters to handle noisy industrial power sources.EMC and ESD Compliance:

Ensure the final design meets IEC/EN standards for electromagnetic compatibility.Storage Reliability:

Use industrial-grade eMMC or SD cards with wear leveling and extended write endurance.Environmental Durability:

Choose conformal coatings and sealed enclosures for dust and humidity protection.

Comparing Android SBCs to Traditional HMIs

| Feature | Traditional HMI | Android SBC-Based HMI |

|---|---|---|

| Operating System | RTOS / Proprietary | Android (Linux-based) |

| UI Design Tools | Vendor-specific | Android Studio / Kotlin |

| Connectivity | Limited | Ethernet, Wi-Fi, MQTT, HTTP |

| Multimedia Capability | Minimal | Full HD / 4K with GPU |

| AI and Vision Support | None | Integrated NPU / GPU |

| Update Method | Manual | OTA (Over-the-Air) |

| Cost per Unit | High | Moderate–Low |

| Ecosystem | Closed | Open and expandable |

This comparison highlights how Android SBCs enable not only richer user interfaces but also long-term scalability and smarter automation workflows.

Future Trends in Android-Based Industrial Systems

1. Integration with Edge AI and Machine Learning

Industrial SBCs are increasingly embedding AI acceleration units.

Future factory HMIs will not only display data but also analyze it locally — predicting failures, optimizing efficiency, and learning operator behaviors.

2. Cloud-Connected Maintenance Platforms

Android-based HMIs will connect to centralized maintenance dashboards, automatically reporting issues, firmware states, and environmental conditions.

3. Cross-Platform Interoperability

Upcoming Android versions are introducing enhanced Linux kernel real-time patches and containerization features, improving compatibility with legacy SCADA systems and cloud orchestration tools like Docker or Kubernetes.

4. Sustainable and Modular Design

Manufacturers are moving toward SOM (System-on-Module) architectures, allowing quick upgrades to newer CPUs without redesigning entire boards — reducing electronic waste and cost over time.

Conclusion

Android SBCs have redefined what industrial automation systems can achieve.

By merging intuitive touchscreen interfaces, robust connectivity, and flexible software development, they bridge the gap between human interaction and machine intelligence.

From factory floors to smart energy systems, Android SBCs provide the adaptability and scalability modern industries need to remain competitive in an interconnected world.

As technology advances, these compact yet powerful boards will continue driving the evolution of automation — making control systems smarter, more efficient, and more human-centered.